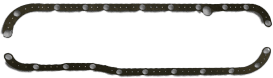

Utilizing an advanced progressive stamping process and a 110 ton capacity straight side press with automatic coil feeding system, Metal Tech Company, Inc. custom fabricates an oil pan gasket for a customer in the automotive industry. This gasket is composed of SAE designated 1010/1008 carbon steel in a thickness of 0.024” and is used to seal a car’s oil system. Manufacturing processes including stamping, punching, and forming are used to achieve the specified contours. Gaskets are completed using an automated assembly procedure for mounting inserts. Finished dimensions are 22.38” in length and 0.73” in width, both held to tolerances of ± 0.005″. After manufacturing, the parts are cleaned in a post-production degreasing process.

The long-term contract requires monthly production of approximately 60,000 assembled gaskets for this automotive industry supplier. Quality is assured with proprietary product performance guidelines and continuous quality control inspection protocol. Metal Tech specializes in high quality custom metal fabrications for a range of industries and applications. For more about this oil pan gasket project or the other value added fabrication capabilities available from the company, please see the table below or contact Metal Tech directly.